Basic Process Control System

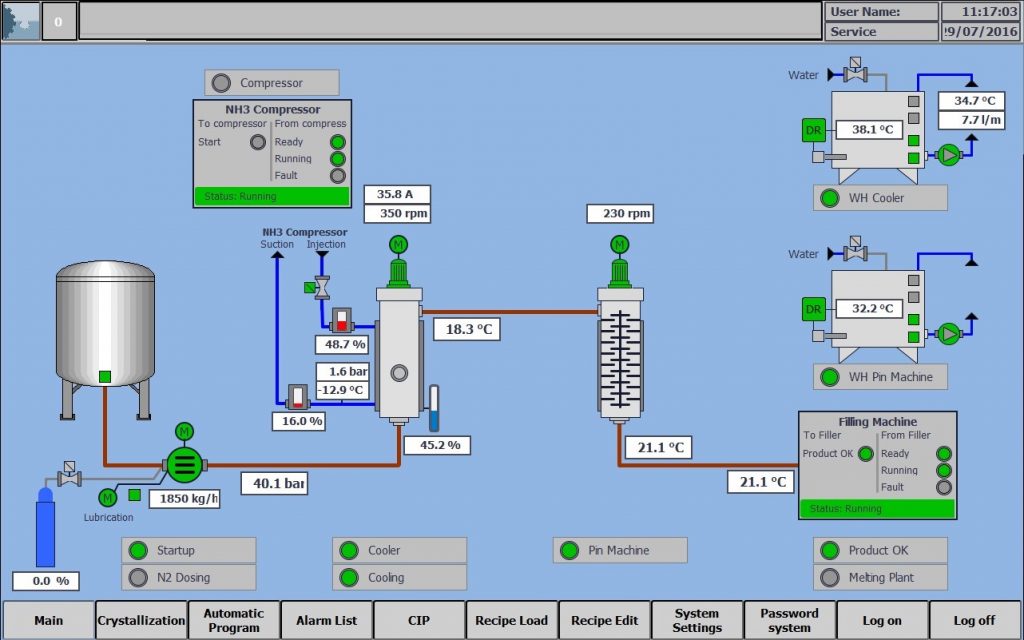

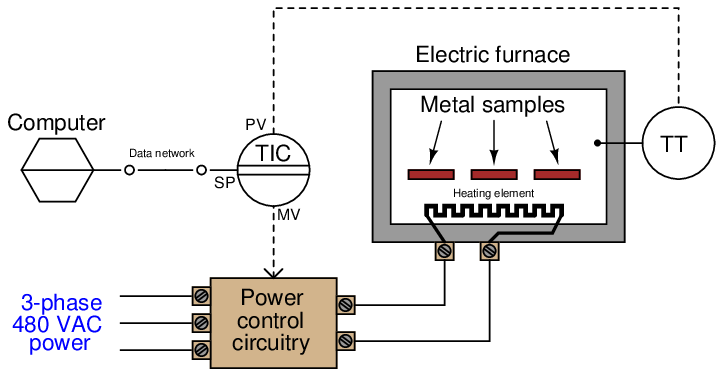

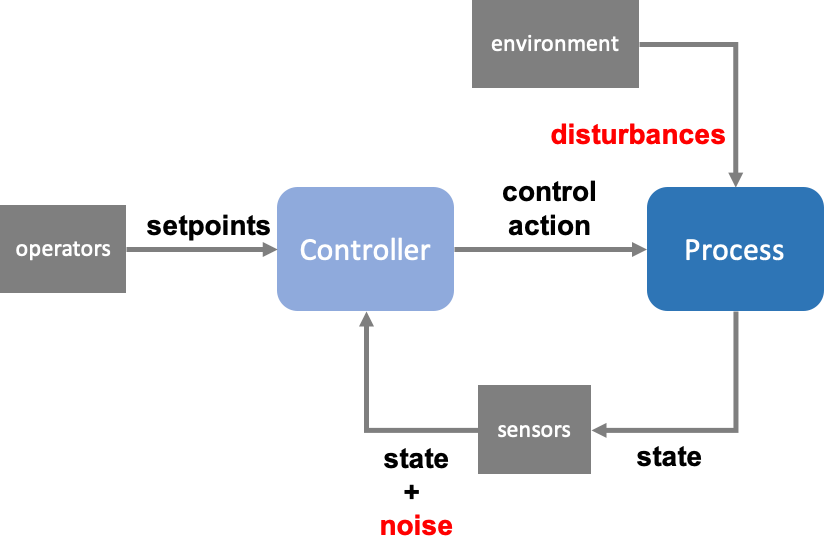

Basic process control system. Control valve influencing the process which is sensed again by. The manipu- lated variables disturbances and the controlled variables Figure 1-1. Understanding the complex systems in automation begins with the basics such as print reading.

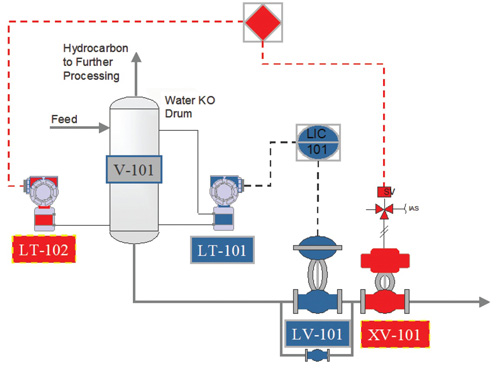

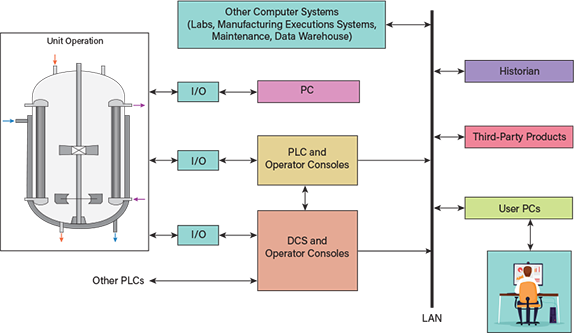

As automation continues to advance our capabilities it also increases the difficulty of maintaining the system. Basic Process Control System BPCS A system that responds to input signals from the process and its associated equipment other programmable systems andor from an operator and generates output signals causing the process and its associated equipment to operate in the desired manner and within normal production limits. The tank will require a supply to maintain its level and therefore the pump s positive suction head at a fixed predetermined point.

A unique system performs both normal and safety functions only for low SIL values separated. Information from the measuring device eg. Steam Process Stream TitCqtm 3s Inlet Outlet.

Ad Delivering Exclusive Access To PAC Experts And Our Full Line Of PAC Products. For a particular example let us look at an open tank which supplies a process say a pump at its output. Variables to control are the quantities or conditions that are measured and controlled.

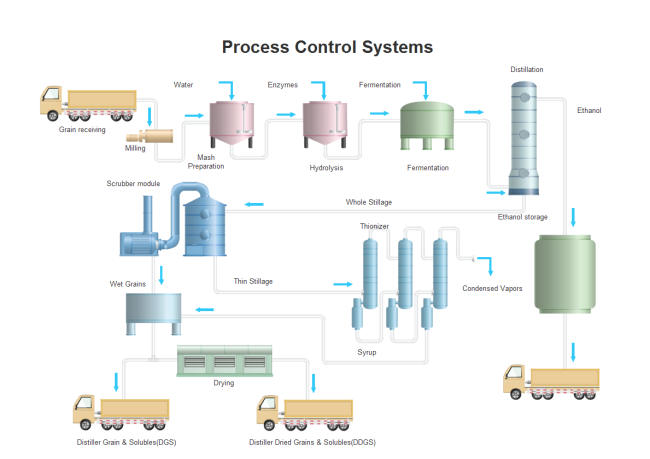

Chapter 34 - Basic Process Control Strategies and Control System Configurations. The latter may be implemented by automatic sequences or procedurally under manual control. Process control begins with understanding your process variables.

To maintain desired conditions in a physical system by adjusting selected variables in the system. A control strategy similar to ratio control is relation control. Control of a Heat Exchanger 7.

A simple control system drawn in block diagram form looks like this. WHAT DOES A FEEDBACK SYSTEM DO.

Bigger is definitely not better in control system design.

Because of the typical. SCAI can be implemented using basic process control system BPCS or safety instrumented system SIS equipment. To maintain desired conditions in a physical system by adjusting selected variables in the system. Understanding the complex systems in automation begins with the basics such as print reading. You must understand the process before you control it. Process control begins with understanding your process variables. A unique system performs both normal and safety functions only for low SIL values separated. Basic process control system and emergency shutdown system share the same communication infrastructure. The simplest control system that will do the job is the best.

Variables to control are the quantities or conditions that are measured and controlled. Chapter 34 - Basic Process Control Strategies and Control System Configurations. Because of the typical. The manipu- lated variables disturbances and the controlled variables Figure 1-1. Ad Delivering Exclusive Access To PAC Experts And Our Full Line Of PAC Products. Basic Process Control System. Variables to control are the quantities or conditions that are measured and controlled.

Post a Comment for "Basic Process Control System"